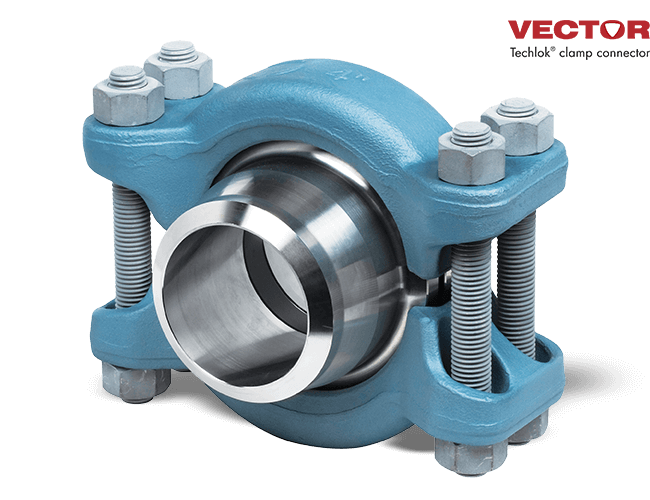

Vector Techlok® Clamp Connector

Vector Techlok® clamp connectors are one of the most effective and economical pipe connection systems available today

External loadings are an inevitable part of any piping system, resulting in high stresses being placed on pipe joints. Independent strain gauges and destructive tests have shown the Vector Techlok® connector can withstand considerable bending moments and axial forces under pressure without leaking or the bolts becoming loose, greatly reducing maintenance costs at the same time as being highly beneficial to the environment.

High pressure systems are not a problem, with Vector Techlok® clamp connectors working in applications where pressures up to 60,000psi are found. For offshore applications, where topside loading is critical, Techlok’s low weight is a significant advantage, a factor applicable in any industry where weight and overall installation cost is a consideration.

Benefits

- Size & Weight

Up to 75% lighter and significantly smaller than a comparable ANSI or API flange.

- 360° Orientation

Radial bolting on our clamp connector allows 360° orientation around the pipe.

- Less Bolting, No Alignment

Only 4 bolts to tighten rather than up to 24 on a conventional flange, with no bolt holes to align.

- Minimize Maintenance Downtime

Much quicker make-up and release time.

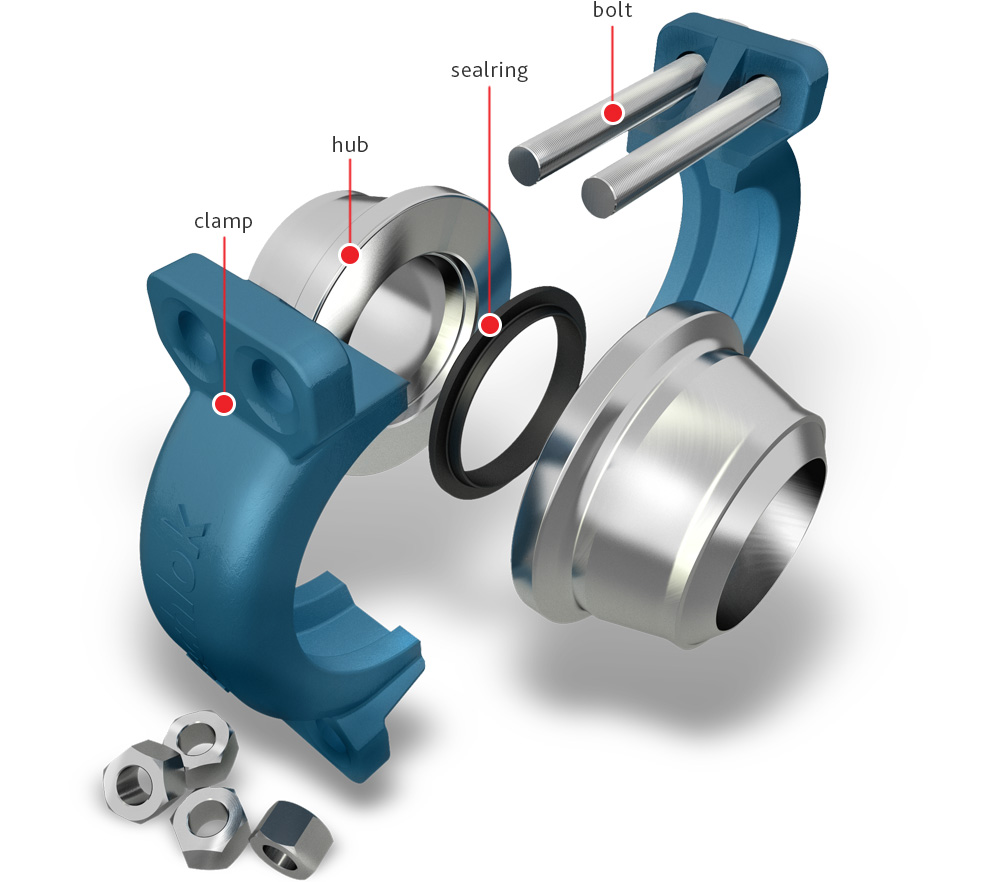

The four basic elements of the Vector Techlok® clamp connector are hubs, sealring, clamps and bolting. When bolting the assembly, the hubs are drawn together by the twin wedge action of the two clamp segments compressing on the sealring to make the first-stage self-energizing seal.

External bending forces

Both bending and axial force have no impact on the pressure energization of the Vector Techlok® metal-to-metal seal, in contrast with conventional flange connections.

Design Codes and Regulations