Vector Slimlok Slim-line compact clamp connector

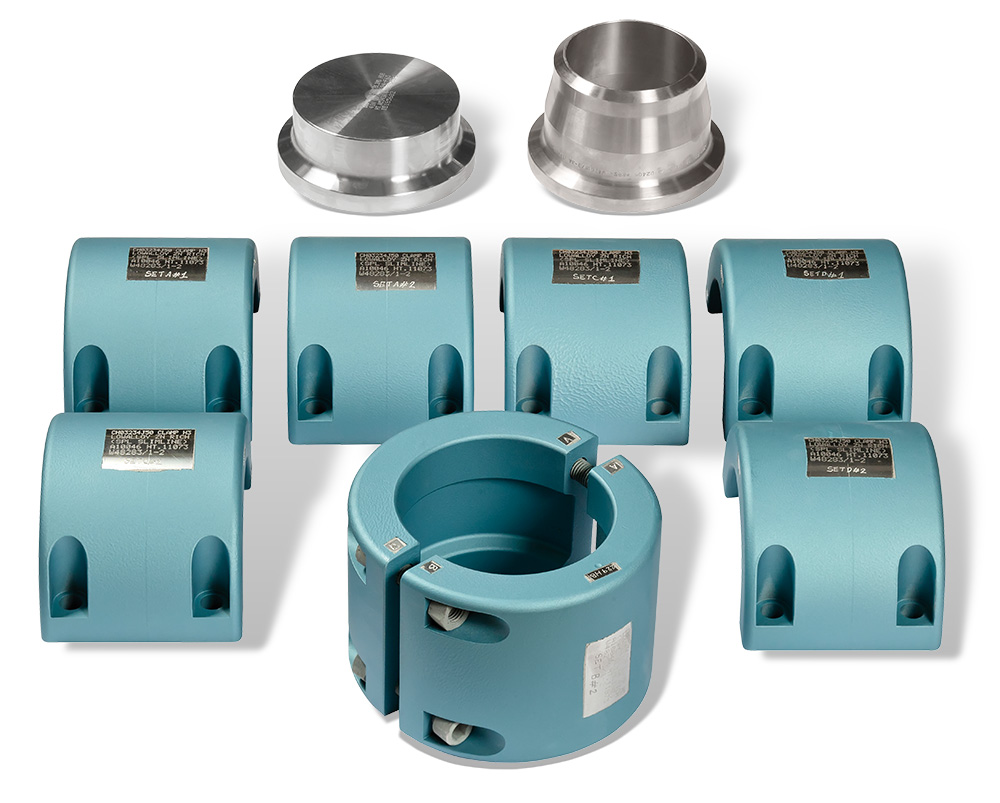

Vector Slimlok Clamps are machined from open-die forgings in a lugless configuration

Description

Vector Slimlok Clamps are machined from open-die forgings in a lugless configuration to provide a more compact and slimline connector and can provide a custom solution to your engineering problem.

Freudenberg Oil & Gas Technologies proprietary software, Vector Analysis, allows reduced envelope clamps to be rapidly developed for a range of pressure, bending and axial loading conditions.

Additionally, having a fully machined construction, Vector Slimlok Clamps can be manufactured from specialized materials.

Vector Slimlok sealring technology

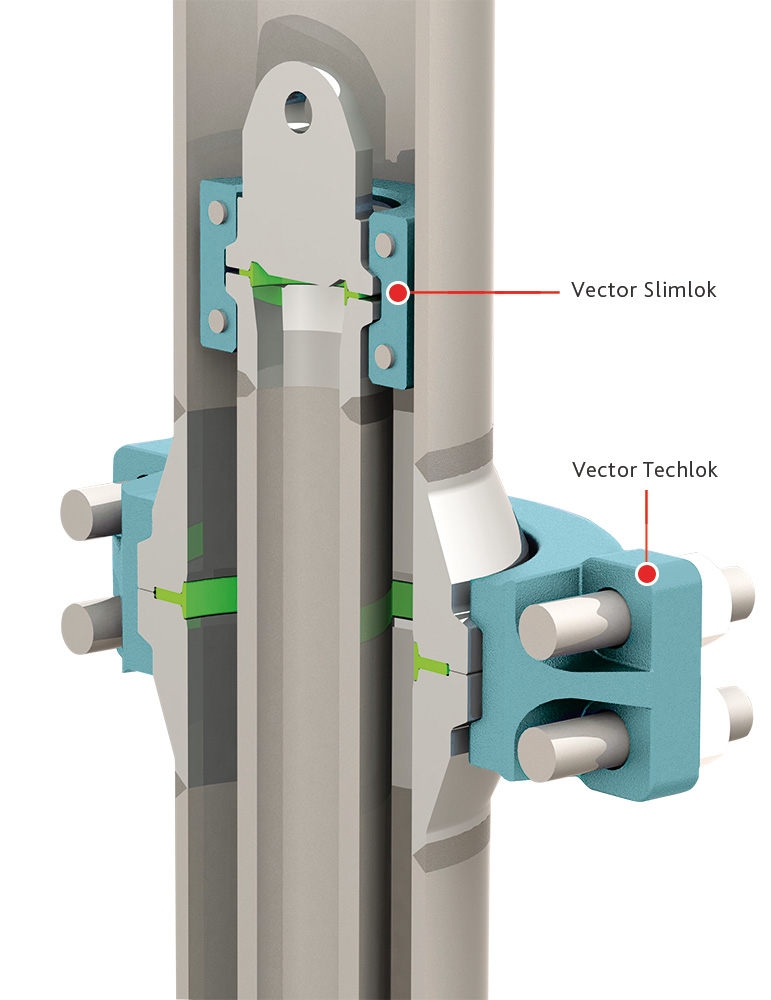

Vector Slimlok Clamps are designed using the same engineering principles and core technology as the Vector Techlok range, utilizing a pressure energized, metal-to-metal seal to provide a compact, high integrity connection. The four basic components of a clamp connector are hubs, sealring, clamps and bolting. When bolting the assembly, the hubs are drawn together by the twin wedge action of the two clamps segments compressing on the seal ring to make the self-energizing seal. The applied bolting loads are transmitted to the clamps through almost 360° contact with the hubs; as the bolts are transversely mounted they are almost completely isolated from the operating loads, resulting in a strong, reliable yet compact connection.

In service the sealring becomes even more effective as the internal pressure reinforces the metal-to-metal seal to the extent that its strength can normally exceed the burst pressure of the connected pipe. The Techlok sealring offers several advantages over conventional gaskets types; for example, the gasket forces and seal diameter are minimal, meaning that the load capacity of the components is maximized and the lack of a conventional flange gasket gives a gas-tight metal-to-metal seal.

Pressure energized sealing

The Techlok sealring offers several advantages over conventional gaskets types; for example, the gasket forces and seal diameter are minimal, meaning that the load capacity of the components is maximized and the lack of a conventional flange gasket gives a gas-tight metal-to-metal seal.

Slimlok clamp applications

Vector Slimlok Clamps can be used in a range of engineering applications, and are particularly suited to:

- Pipe-in-pipe application

- Pulling head connections

- High Pressure umbilical connectors

- Compact clamping on valve bonnets and vessels

- Any application where there is a risk of snagging when using a standard, lugged, connector

Slimlok clamps can be designed to comply with

- ASME B31.3 / ASME VIII Div2 Part 5

- API 6A / ISO 10423

- PD 5500

- UK Offshore Regulations

- Customer’s special requirements

- Country codes

- Norsok

- PED (Pressure Equipment Directive)

Material

Being machined from open die forgings Vector Slimlok clamps can be custom made from any machinable metal. Freudenberg Oil & Gas Technologies hasexperience manufacturing clamp connectors from carbon steel, Duplex and Super Duplex stainless steels, nickel alloys and other specialist materials.

Bolting

Vector Slimlok Clamps can be designed using a range of bolting configurations to suit customer requirements.

To maintain a reduced envelope Slimlok clamps typically have smaller bolt areas than other clamp connectors of an equivalent diameter; stronger bolting materials can be specified at the design stage to help meet pressure, bending load or axial force requirements.

简体中文

简体中文