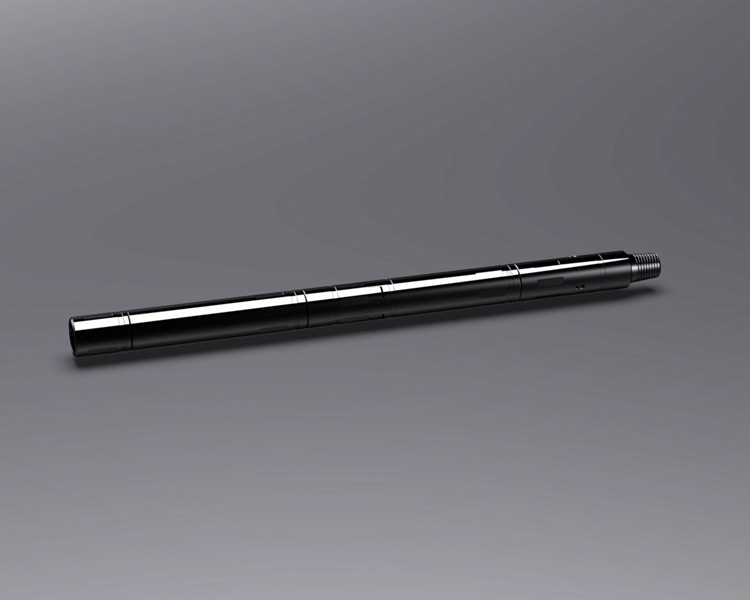

GDI 2.125″ Heavy Duty Motorhead, Assembly – 1.500″ AMMT 0303.0540.000.0

Description

Global Dynamics Motorhead Assembly combines our Dual Flapper Check Valve, our Heavy Duty Hydraulic Disconnect, as well as the Dual Activated Circulation Sub. The choice of tubing connector is not dictated by the Motorhead, therefore giving the operator the flexibility to choose the most appropriate connector to suit the application. With a considerable reduction in the number of component parts, seals and thread connections, the Motorhead Assembly is uncomplicated to assemble/disassemble and inexpensive to redress.

The Ball Operated HD release tool is specifically designed for use with drilling tools and other applications that transmit torque. Straight pickup separates the coiled tubing and the BHA, allowing for retrieval of the coiled tubing. The bottom half of the sub can then be fished. With an overall length of 35.69” (0.907m), the Motorhead Assembly is a compact design compared to conventional individual components.

Features & Benefits

- Rated to working pressure of 10,000 psi

- Temperature rating of up to 150°C

- Impact, shock loading, torque and straight pull tolerant design

- Suitable for H2S environments

- Ideal for drilling and milling applications

- Includes ball operated circulation sub with burst disk backup

- Dual flapper check valves

- Heavy duty hydraulic disconnect

Additional information

| Weight | 26 lbs |

|---|---|

| TOOL OD (in) | 2.125 |

| TEMP RATING(℉) | 302 |

| PRESSURE RATING(PSI) | 10,000 |

| TENSILE YIELD(lbf) | 50,000 |

| TORQUE(ft-lb) | 1,000 |

| THREAD TYPE | |

| COUNTRY OF ORIGIN | Canada |

简体中文

简体中文