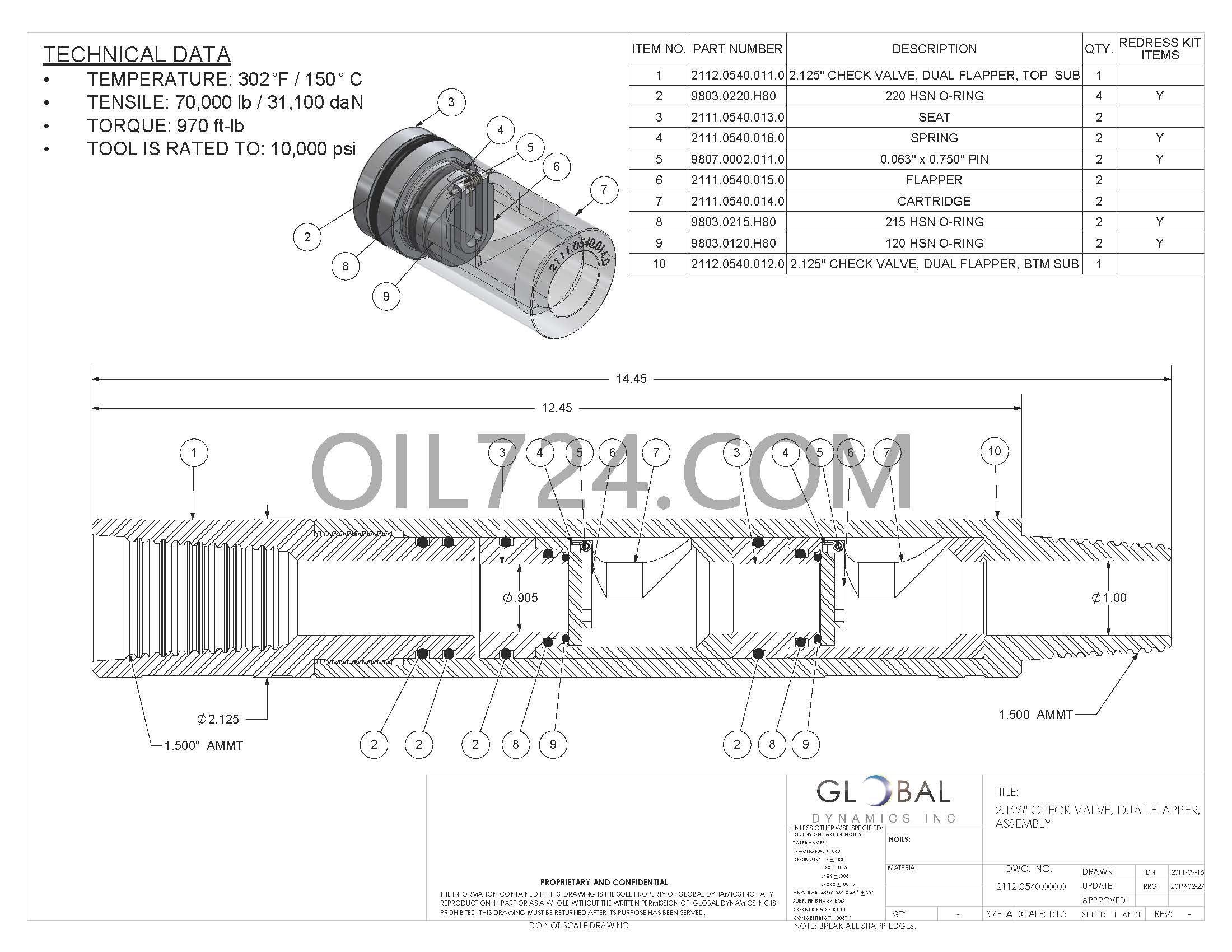

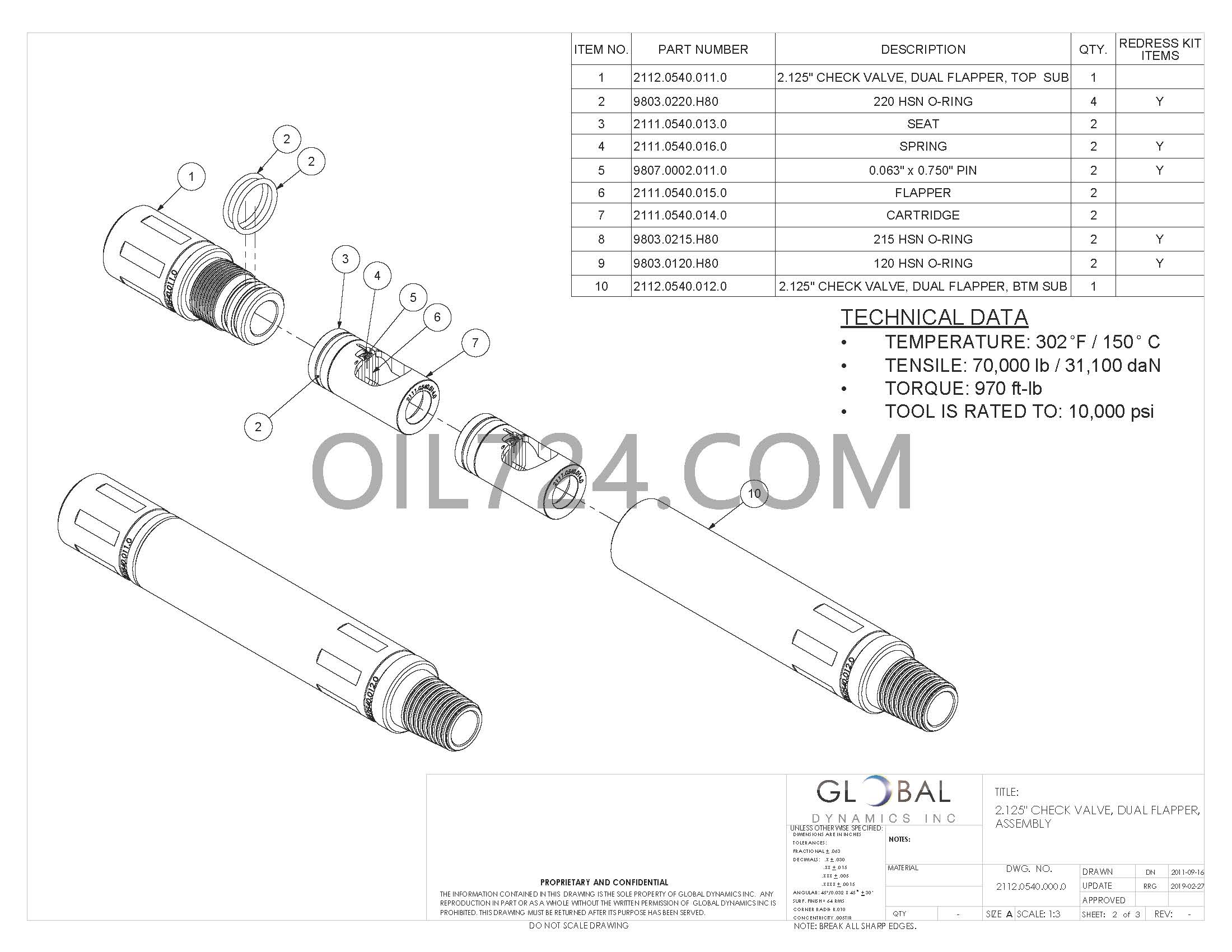

GDI 2.125″ Dual Flapper Check Valve, Assembly – 1.500″ AMMT Box x Pin 2112.0540.000.0

Description

Used to eliminate flow-back from the wellbore, the Dual Flapper Check Valve’s spring loaded valves provide maximum flow area while also ensuring high performance sealing capabilities. Risk of failure is virtually eliminated through the dual sealing arrangement.

The Dual Flapper Check Valve is a standard coiled tubing string component and is frequently run with drilling motor strings for work-over and completion operations. The tool ensures safe operation when running coiled tubing into high-volume, high-pressure or H2S environments. When run above Mechanical or Hydraulic Release Tools, the Flapper Check Valve’s large ID design allows passage of disconnect balls or darts, and reduces unnecessary back pressure on the surface pumps. The GDI Flapper Cartridge housing incorporates a simple ‘drop-in and thread’ design with the Dual Flapper Check Valve housings, providing ease of assembly.

Additional information

| Weight | 9 lbs |

|---|---|

| TOOL OD (in) | 2.125 |

| TEMP RATING(℉) | 302 |

| PRESSURE RATING(PSI) | 10,000 |

| TENSILE YIELD(lbf) | 70,000 |

| TORQUE(ft-lb) | 970 |

| THREAD TYPE | |

| COUNTRY OF ORIGIN | Canada |

简体中文

简体中文