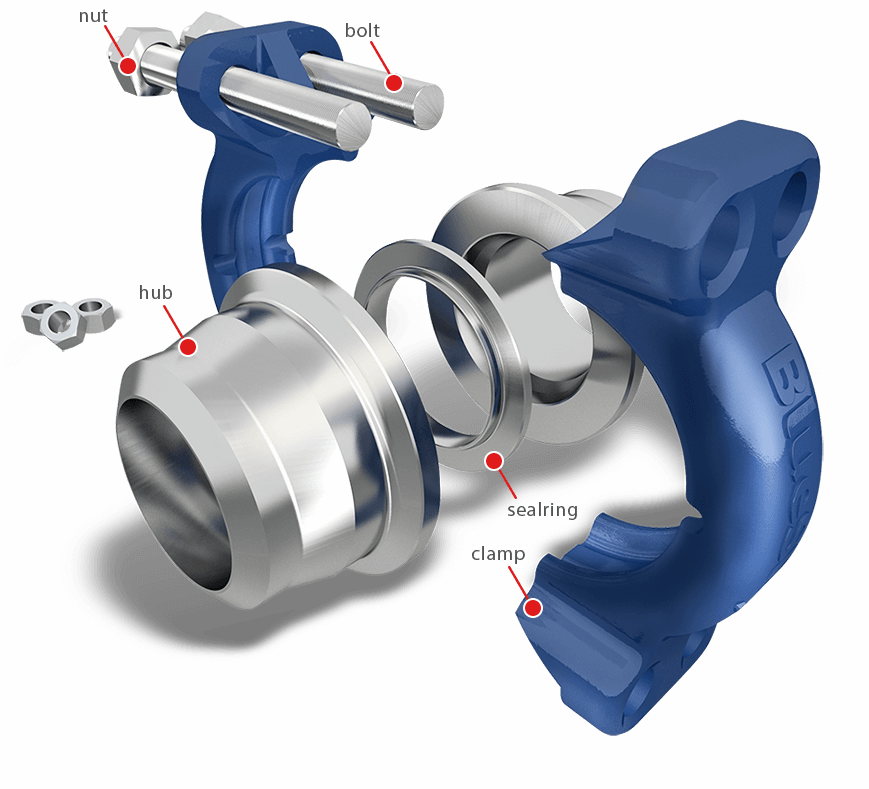

BlueSky Bluelock Clamp Connector CC0150-013-037

1.5″ BlueLock Clamp Set Includes: 2 clamp halves, 4 studs, 8 nuts

$480.00 Including Tax is $623.76

Available on backorder

Description

The BlueSky BlueLock clamp connector is a reliable, easy-to-assemble, metal-to-metal sealed connector designed for use in piping systems requiring high integrity seals in applications involving corrosive, erosive, high temperature, high pressure, and cyclic conditions. It is engineered for pressure vessel nozzles and closures, process piping, compressors, pumps, manifolds, and valves.

The seal ring is a zero leakage, reusable, metal-to-metal gasket interfaced with the hub sealing surface to ensure high integrity and a reliable seal. The joint configuration ensures that the seal ring is elastically loaded during assembly to offer a self energized seal during operation.

Benefits

- Simple 4 Bolt Connection

Just 4 bolts to install, compared with 8-24 bolts for conventional flanges. The BlueLock connector is still effective even when the tightening of bolts is uneven.

- Lower bolt torque

Lower torque requirements, no requirement for special hydraulic tensioning.

- Smaller & Lighter

The efficient design results in a BlueLock connector that is substantially smaller in size and much lighter in weight when compared to an equivalent ANSI or API flange class.

- Decrease Downtime

Quick assembly/disassembly with fewer bolts –and parts- overall, no bolt holes to align.

The Bluelock sealing technology

( 1 ) The rib of the seal ring is clamped between the hub faces. The rib of the seal ring assists with proper alignment as the connector is clamped together.

( 2 ) The seal ring lips engage the inner hub surface. The rib controls the amount of seal ring lip deflection within the elastic range.

( 3 ) The seal ring lips deflect inwards to achieve a highly reliable metal-to-metal seal.

( 4 ) Internal pressure acts on the inside face of the seal ring lips and pressure energizes the seal to enhance the reliability of the metal-to- metal seal. This feature is significantly superior to traditional flanges in which pressure acts directly on the flange faces, forcing them apart and impacting the integrity of the seal.

Additional information

| Weight | 10.5 lbs |

|---|

简体中文

简体中文